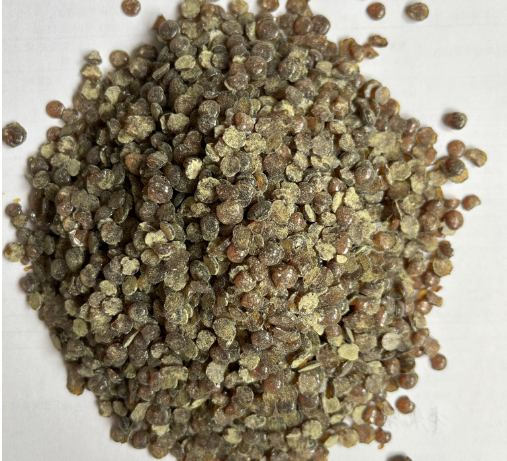

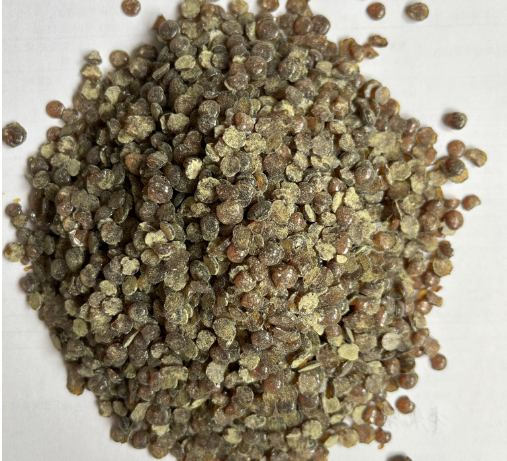

一、 Product presentation

It is a solid resin of brown to dark brown granular or sheet thermoplastic, mainly by the by-production of carbon nine fractions and carbon nine fractions of ethylene device divided into raw materials, through special production process, under certain temperature and pressure conditions, low molecular weight between 300-3000.It has the characteristics of low acid value, good miscibility, water resistance, ethanol resistance and chemical resistance, has chemical stability to acid and base, and has good regulation of viscosity and thermal stability.C9 petroleum resin is generally not used alone, but is used together as promoters, regulators, modifiers and other resins.

二、 Application area

A. Paint: The paint mainly uses C9 petroleum resin with high softening point. The addition of petroleum resin can increase the gloss of the paint and improve the adhesion, hardness, acid resistance and alkaline resistance of the paint film.

B. Tires and rubber: Tyres and rubber mainly use C9 petroleum resin with low softening point.This kind of resin and natural rubber rubber have good mutual compatibility, has no great effect on the rubber vulcanprocess, the addition of petroleum resin in tires and rubber can play the role of bonding, strengthening and softening.

C. Ink industry: petroleum resin for ink is mainly a high softening point of petroleum resin. The addition of petroleum resin in the ink can play the effect of color exhibition, fast drying and brightening, and improve the printing performance.

D. Asphalt modifier: Asphalt modifier mainly uses C9 petroleum resin with high softening point to improve the viscosity of asphalt and improve the performance of asphalt. It is an indispensable asphalt modifier for the production of color pavement, running, stadium and other sports venues in the community.